Choosing the Best Fall Protection

Date Posted: 01/27/2024

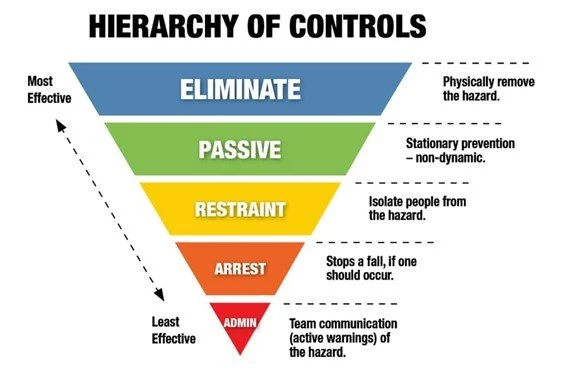

According to the WA Department of Labor and Industries, Falls account for more than 1/3 of all fatalities in Construction in WA State. (36% between 2018-2022 Labor and Industries). In 2020, nationally, there were 351 fatal falls to a lower level out of 1,008 construction fatalities (BLS data). These fatalities are preventable. Unfortunately, all fall protection methods are not equal, and often when choosing fall protection solutions, many tend to go directly to “tying-off.” This is not the best choice as there is a hierarchy of solutions that should always be evaluated – in order – to determine which is the safest, most effective one. Fall hazards are foreseeable, and the best way to prevent falls is to utilize the Hierarchy of Fall Protection.

Eliminate

A fall hazard that doesn’t exist can’t cause an injury, so the best solution is to ensure the risks are eliminated. The first step in the Hierarchy of Fall Protection is elimination. Elimination means finding an approach to a task that does not place a worker in a position where they could be at risk of a fall injury. Hazard elimination is completely removing a hazard via construction or maintenance. It means that the risk of falling has been completely prevented.

Example: have a worker use a light bulb changer pole to replace light bulbs rather than have that worker climb a ladder to reach the bulb.

Passive

The second step is Passive protection. Passive protection is generally considered to provide a higher level of safety since the opportunity for error is lesser than using personal protective equipment (PPE). Passive fall prevention includes physical barriers that keep workers away from edges that present fall hazards.

Example: Including guardrails or railings along the edge of an upper level that keeps workers away from high-risk edges. The requirements for guardrail systems are found in WAC 296-880-40005.

Restraint

When elimination or passive systems are not feasible, workers should consider work restraint. Restraint uses personal fall prevention PPE (harness, lanyard, and anchor point) to restrain the worker’s range of motion, preventing them from reaching the edge and being exposed to a fall hazard. Because of this configuration, this type of “tying-off” prevents the user from being able to fall in the first place. Fall restraint systems are always preferred over fall arrest systems because they eliminate the need for a fall rescue plan for a worker suspended at heights and the fall clearance needed for fall arrest. In accordance with WAC 296-880-40025, a full body harness must be used when using fall restraint. Body belts are prohibited.

Arrest

The fourth step in the Hierarchy of Fall Protection is fall arrest, which is distinctly different from the previous three steps. Unlike those steps, which protect workers by preventing falls, fall arrest systems protect workers by stopping them after a fall happens. Like fall restraint systems, fall arrest systems use full-body harnesses, lifelines, and anchor points. However, the lifelines on fall arrest systems are either energy (shock) absorbing lanyards or self-retracting lifelines (SRL). The standards for personal fall arrest are found in WAC 296-880-40020.

Administrative Controls

Administrative controls are the least effective method in the fall protection hierarchy. Administrative controls are work practices or procedures that increase a worker’s awareness of a fall hazard. These preventative measures are taken to reduce the likelihood of a fall. Administrative controls like warning lines, safety monitors, and control lines are best when combined with other fall protection methods. However, administrative controls are easy to ignore and are considered the least effective method.

Examples Include safety monitors, warning lines, warning horns, designated areas, or control lines.